Design Manual for Roads and Bridges

Pavement

Inspection & Assessment

CS 230 Pavement maintenance assessment procedure

(formerly HD 29/08, HD 30/08)

Version 0.1.0

Summary

This document sets out the requirements for reviewing routine/network level data in order to establish whether there is a pavement maintenance need that requires further investigation. The review will identify lengths of pavement, some of which will be selected for detailed investigation. This document is complemented by CD 227 which sets out the requirements for determining the need for maintenance and for designing maintenance treatments, and by CS 229 which sets out the requirements for undertaking detailed pavement investigations. Requirements for assessing skidding resistance on the network are set out in CS 228.

National Variation

This document has associated National Application Annexes providing alternative or supplementary content to that given in the core document, which is relevant to specific Overseeing Organisations. National Application Annexes are adjoined at the end of this document.

Feedback and Enquiries

Users of this document are encouraged to raise any enquiries and/or provide feedback on the content and usage of this document to the dedicated National Highways team. The online feedback form for all enquiries and feedback can be accessed at: www.standardsforhighways.co.uk/feedback.

This is a controlled document.Latest release notes

| Document Code | Version number | Date of publication of relevant change | Changes made to | Type of change |

|---|---|---|---|---|

| CS 230 | 0.1.0 | December 2022 | Core document, England NAA | Incremental change to requirements |

| [PUB. Dec. 2022] Contains updated requirements covering legacy concrete pavements. | ||||

Previous versions

| Document Code | Version number | Date of publication of relevant change | Changes made to | Type of change |

|---|---|---|---|---|

| CS 230 | 0 | March 2020 |

Foreword

Publishing information

This document is published by National Highways.

Together with CS 229 [Ref 1.I] and CD 227 [Ref 1.N], this document supersedes HD 29/08 and HD 30/08, which are withdrawn.

Contractual and legal considerations

This document forms part of the works specification. It does not purport to include all the necessary provisions of a contract. Users are responsible for applying all appropriate documents applicable to their contract.

Introduction

Background

Road pavements do not last indefinitely. At some stage in their lives signs of wear such as polishing, rutting, fretting and cracking may show on the surface. Maintenance is required when these signs of wear are judged to affect the standards of service provided to the road user and the integrity of the pavement structure.

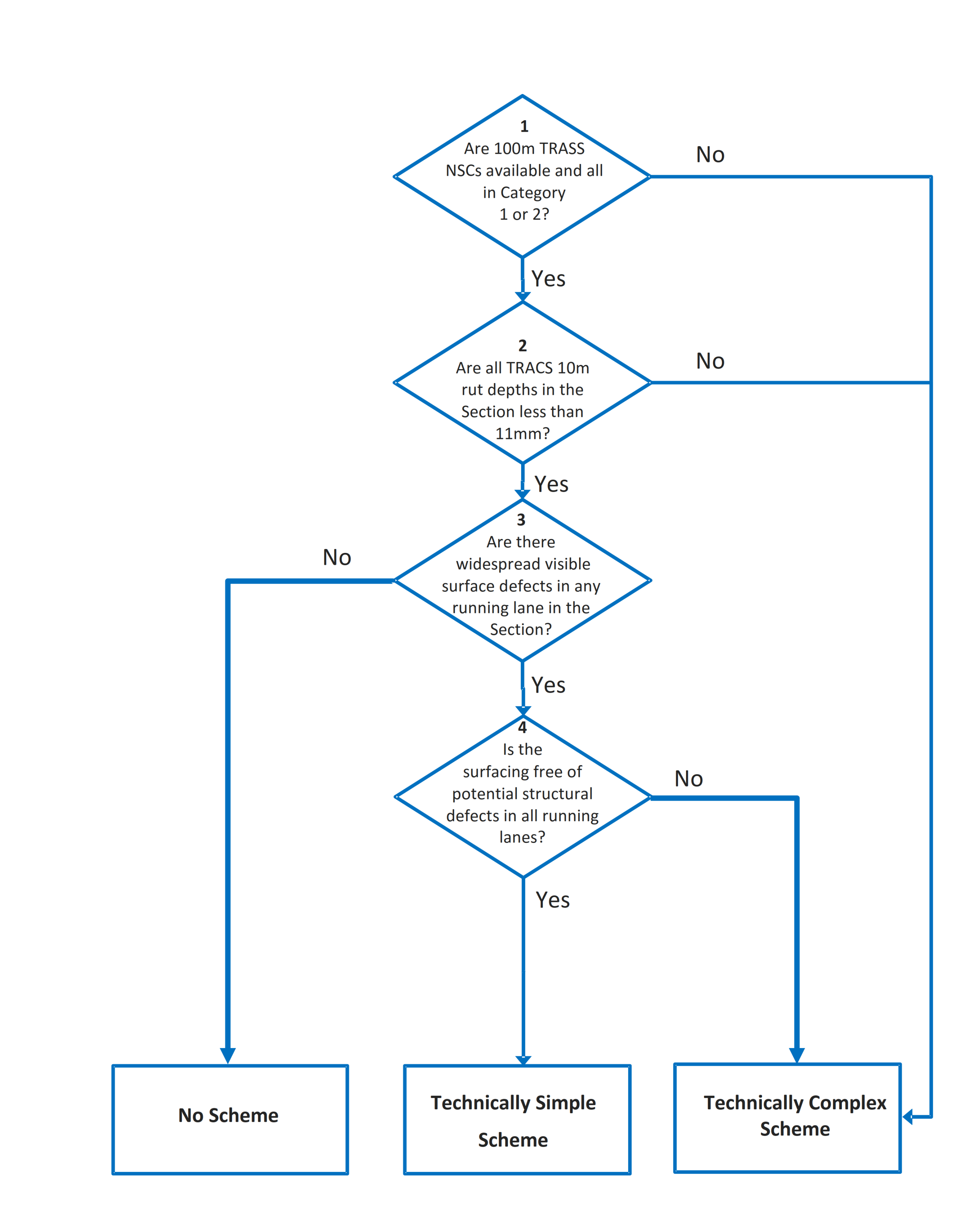

The Overseeing Organisations use a hierarchical approach to assess the needs of the carriageways on motorways and all-purpose trunk roads:

1) Network-level surveys, undertaken on a routine basis, are used to identify lengths of pavement that potentially require maintenance. Wherever possible these surveys are undertaken at traffic speed. The requirements for this process are set out in this document. Requirements to be used to determine and assess skidding resistance on the network are set out in CS 228 [Ref 2.I].

2) Once a length has been identified as requiring maintenance then a detailed investigation is required to determine the maintenance need and to provide the information required to design the appropriate maintenance treatments. The requirements for this process are set out in CD 227 [Ref 1.N].

3) The technical requirements and associated advice for collecting the scheme-level data required to support this process are set out in CS 229 [Ref 1.I].

Assumptions made in the preparation of this document

The assumptions made in GG 101 [Ref 2.N] apply to this document.

Mutual recognition

Where there is a requirement in this document for compliance with any part of a "British Standard" or other technical specification, that requirement may be met by compliance with the Mutual Recognition clause in GG 101 [Ref 2.N]Introduction to the Design Manual for Roads and Bridges (as the standard text in MDD v6 cl 4.39).

1. Scope

Aspects covered

1.1 The requirements in this document shall be used to identify lengths of pavement on the carriageways of the Overseeing Organisations’ motorway and all-purpose trunk road network that require maintenance.

NOTE 1 The requirements for undertaking detailed investigations for determining maintenance need and providing the information required to design the appropriate maintenance treatments are set out in CD 227 [Ref 1.N].

NOTE 2 The technical requirements and associated advice for collecting the scheme-level data required to support the design process are set out in CS 229 [Ref 1.I].

NOTE 3 This document does not cover skid resistance. Requirements for determining and assessing skidding resistance on the network are set out in CS 228 [Ref 2.I].

Implementation

1.2 This document shall be implemented forthwith on all schemes involving the design of pavement renewals on the Overseeing Organisations’ motorway and all-purpose trunk roads according to the implementation requirements of GG 101 [Ref 2.N].

Use of GG 101

1.3 The requirements contained in GG 101 [Ref 2.N] shall be followed in respect of activities covered by this document.

2. Network level surveys

2.1 This section sets out details of the network level pavement condition surveys that shall be undertaken and used to identify lengths of pavement that require maintenance.

NOTE 1 Network level surveys are carried out on a routine basis on the Overseeing Organisations’ motorway and all-purpose trunk roads. Wherever possible these surveys are undertaken at traffic speed.

NOTE 2 Network level surveys can be categorised as surface condition or structural condition.

Surface condition surveys

2.2 Surface condition surveys shall be undertaken on the Overseeing Organisations’ motorway and all-purpose trunk roads in accordance with the National Application Annex (NAA).

NOTE 1 Surface condition surveys are undertaken at traffic speed using survey vehicles equipped with sophisticated measurement apparatus.

NOTE 2 Typically surface condition surveys provide data on rutting (transverse profile), ride quality (longitudinal profile), texture depth and road geometry (gradient, crossfall and curvature). They can include collection of forward and downward facing images.

NOTE 3 Some of the data collected by surface condition surveys can be used to provide information on the structural condition of the pavement.

NOTE 4 Skidding resistance is a property of surface condition. This document does not cover skidding resistance. Requirements for determining and assessing skidding resistance on the network are set out in CS 228 [Ref 2.I].

Structural condition surveys

2.3 Structural condition surveys shall be undertaken on the Overseeing Organisations’ motorway and all-purpose trunk roads in accordance with the NAA.

NOTE Typically structural condition surveys provide data on the deflection response of the pavement. This data is used to assess the structural strength of the pavement.

3. Other sources of relevant data

3.1 To supplement the data collected from network-level condition surveys, data from other sources shall be used to assist with the identification of lengths of pavement that potentially require maintenance.

3.1.1 Data from the following sources should be used:

- safety inspections;

- other routine inspections that are regularly undertaken to identify the presence of pavement defects;

- records of unplanned and/or reactive maintenance.

NOTE Data from the previous three years are typically used to identify lengths of road that are regularly and/or repeatedly requiring maintenance.

3.1.2 Information from other records and sources of data may be used to assist with the identification of lengths of pavement that require maintenance.

4. Review of data

4.1 The network level survey data (described in Section 2) and the additional data (described in Section 3) shall be collated and reviewed in accordance with the requirements of the NAA in order to identify lengths of pavement for potential maintenance treatment.

NOTE 1 The review involves comparing the outputs from the network level data against threshold levels of condition for different parameters. Lengths where one or more of the parameters exceed the threshold values can indicate the need for further investigation.

NOTE 2 Records of inspections, unplanned maintenance and reactive maintenance from the past three years are typically used to identify additional lengths. These records can also provide supplementary evidence for lengths already identified by the network level surveys.

4.2 Lengths of pavement identified for potential maintenance treatment shall be subject to a visual assessment, either a drive-over or a review of video images, before finalising the list of lengths to be investigated.

NOTE The visual assessment information can provide supporting evidence of the current condition.

4.3 Lengths of pavement identified for potential maintenance treatment shall be selected for further investigation.

4.4 The reasons why lengths have been selected for further investigation shall be documented and retained.

NOTE The list of lengths can be reviewed by the Overseeing Organisation.

4.5 Where further investigations are proposed, these shall be undertaken in accordance with CD 227 [Ref 1.N].

5. Normative references

The following documents, in whole or in part, are normative references for this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

| Ref. | Document |

|---|---|

| Ref 1.N | National Highways. CD 227, 'Design for pavement maintenance' |

| Ref 2.N | National Highways. GG 101, 'Introduction to the Design Manual for Roads and Bridges' |

6. Informative references

The following documents are informative references for this document and provide supporting information.

| Ref. | Document |

|---|---|

| Ref 1.I | National Highways. CS 229, 'Data for pavement assessment' |

| Ref 2.I | National Highways. CS 228, 'Skidding resistance' |